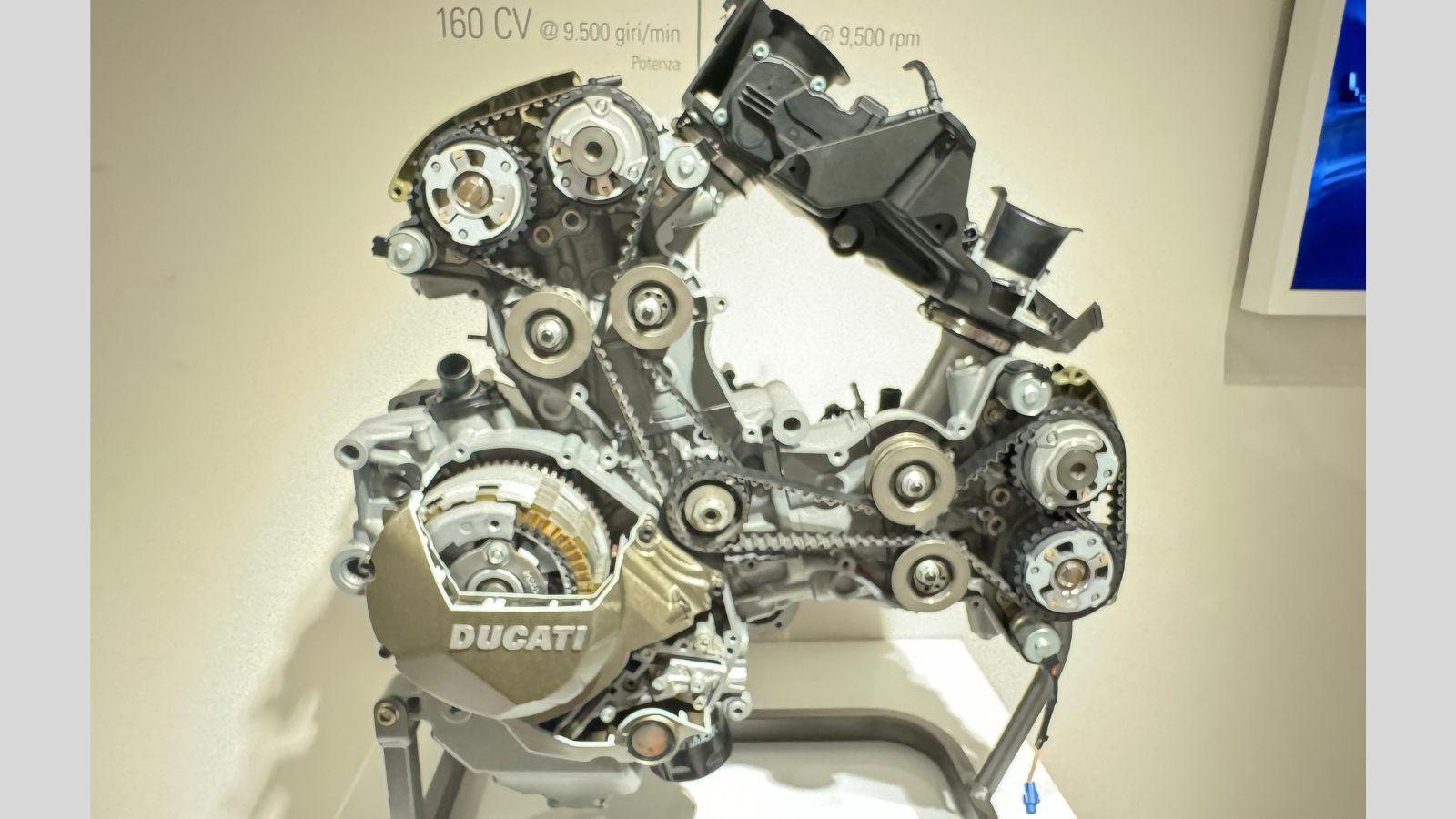

Ducati’s signature L Twin engine is more than just a power plant it’s a symbol of the brand’s philosophy. Technically a 90-degree V twin mounted with the front cylinder nearly horizontal and the rear vertical, the layout resembles an “L” when viewed from the right side. This configuration is not just a stylistic choice, but a deliberate engineering decision that defines how Ducati motorcycles ride and feel.

One of the biggest advantages of the L Twin layout is its perfect primary balance. With the cylinders positioned at 90 degrees, the opposing piston movements cancel out most vibrations without the need for counterbalancers. This results in a smooth, refined power delivery, even in high performance conditions. Additionally, the layout allows for a compact engine design with a low center of gravity, improving stability and handling particularly important in sport and racing applications.

However, there are trade offs. The horizontal cylinder can create packaging challenges, especially in front radiator placement or exhaust routing. Also, compared to inline four configurations, the L Twin can be more expensive to manufacture and service due to its complexity and fewer shared components. Still, Ducati has embraced these challenges to preserve the character and soul that riders have come to love.

The Desmodromic Valve Train: Mechanical Mastery

What truly sets Ducati engines apart from the rest of the motorcycle world is the use of a desmodromic valve system. Rather than relying on traditional valve springs to close the intake and exhaust valves, Ducati’s system uses cam lobes and followers to both open and close the valves mechanically.

This system eliminates the risk of valve float at high rpm, allowing Ducati engines to rev freely and reliably at very high speeds. The desmodromic approach delivers precise valve control and enhanced performance, especially on the track. It was originally pioneered by Mercedes Benz in Formula One during the 1950s, but Ducati adopted and refined it for motorcycle use, making it a hallmark of the brand.

The design was introduced to Ducati by engineer Fabio Taglioni in the late 1950s. Taglioni, often revered as the father of Ducati’s racing legacy, implemented the desmo system in Ducati’s race bikes to gain a competitive advantage. Over the years, Ducati’s engineers have continuously refined the mechanism, adapting it for both race and street applications.

Who Designed and Refined the Engine

The foundation of Ducati’s L Twin architecture and desmodromic system was laid by the legendary Fabio Taglioni. A visionary engineer, Taglioni’s work in the 1950s and 60s shaped the core of Ducati’s identity. His belief in technical innovation, especially the advantages of mechanical valve actuation, made Ducati motorcycles distinctive and competitive.

Following Taglioni’s groundwork, later Ducati engineers such as Massimo Bordi and Pierre Terblanche continued the legacy, evolving the L Twin into the liquid cooled, fuel injected, and electronically managed engines seen in modern Ducatis. The Testastretta and Superquadro series are descendants of this design philosophy, maintaining the core V twin layout while enhancing power, reliability, and emissions compliance.

Dry Clutch vs Wet Clutch: A Ducati Distinction

One of the most iconic sounds in the world of motorcycles is the rattle of a Ducati dry clutch at idle. Ducati has long favored dry clutches for many of its sport and racing models. Unlike a wet clutch, which operates in an oil bath, a dry clutch is exposed to air and runs without lubricant.

The dry clutch has a few key benefits. It allows for faster, more aggressive clutch engagement, making it ideal for racing conditions. It also isolates the engine oil from clutch debris, potentially improving oil longevity and engine cleanliness. Additionally, the unique clatter of the dry clutch has become a kind of mechanical signature a sound that instantly identifies the bike as a Ducati.

However, dry clutches are louder, require more frequent maintenance, and can wear out faster than wet clutches. That is why most modern Ducatis, particularly in their touring and street focused models, have transitioned to wet clutch systems for comfort and durability.

Why Ducatis Rattle at Idle

The famous Ducati rattle, especially on classic models, is due to the design of the dry clutch and the desmodromic valve system. The clutch plates rattle because there is no oil to dampen the metal on metal contact when the lever is disengaged. Combine that with the precise but mechanically noisy operation of the desmo system, and you get a unique symphony of mechanical sound one that aficionados find music to the ears.

Some also note that older Ducatis had looser tolerances than today’s models, which added to the charm and clatter. It’s a sound that says performance, history, and passion all in one rev.

A Legacy of Performance and Identity

The Ducati L Twin engine is not just an internal combustion machine it’s the heartbeat of a legacy. From its distinctive layout and the ingenious desmodromic valve train to its unmistakable sound, every part of the L Twin tells a story. A story of innovation, racing glory, and Italian craftsmanship.

Whether on the racetrack, winding through mountain passes, or idling outside a cafe, a Ducati with an L Twin engine is instantly recognizable. It is more than an engine, its character, soul, and identity one that continues to define Ducati motorcycles to this day.